KILN OPERATION

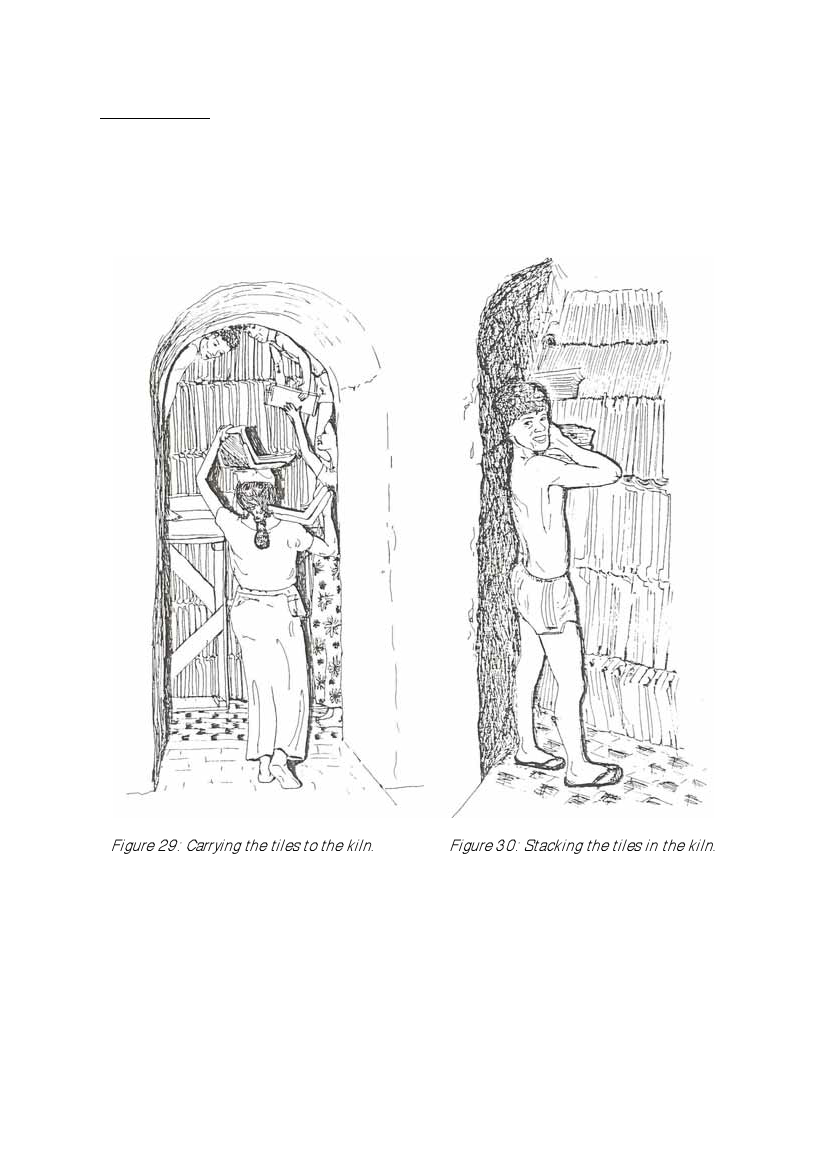

Once dry (having lost about 17 per cent of the wet weight) the tiles are removed from their

pallets and stacked in the kiln. The tiles are stacked upright as close together as they will go.

They are never stacked over six layers high, as any increase in weight will damage the bottom

tiles in firing. If the kiln has extra space on the top of the load flower pots stoves or other light

weight clay products can be fired here.

Figure 29: Carrying the tiles to the kiln.

Figure 30: Stacking the tiles in the kiln.

The kiln is fired for 48 hours, building from small fires up to full fire for the last six hours of

the firing. The tiles must attain at least 8500C to become ceramic. In Sri Lanka a firing of

13,000 tiles requires 50 cubic yards of hardwood. The kiln must cool for about 36 hours

before tiles can be uploaded. For the first six hours after firing the kiln is left completely

sealed, then the chimney dampers are opened, and after 12 hours the ceiling vents on the

kiln are opened. After about 20 hours the top 50cm of the door bricking is removed.

Unloading can proceed as soon as the tiles can be handled. Generally the workers use thick

gloves or pads to carry the hot tiles.